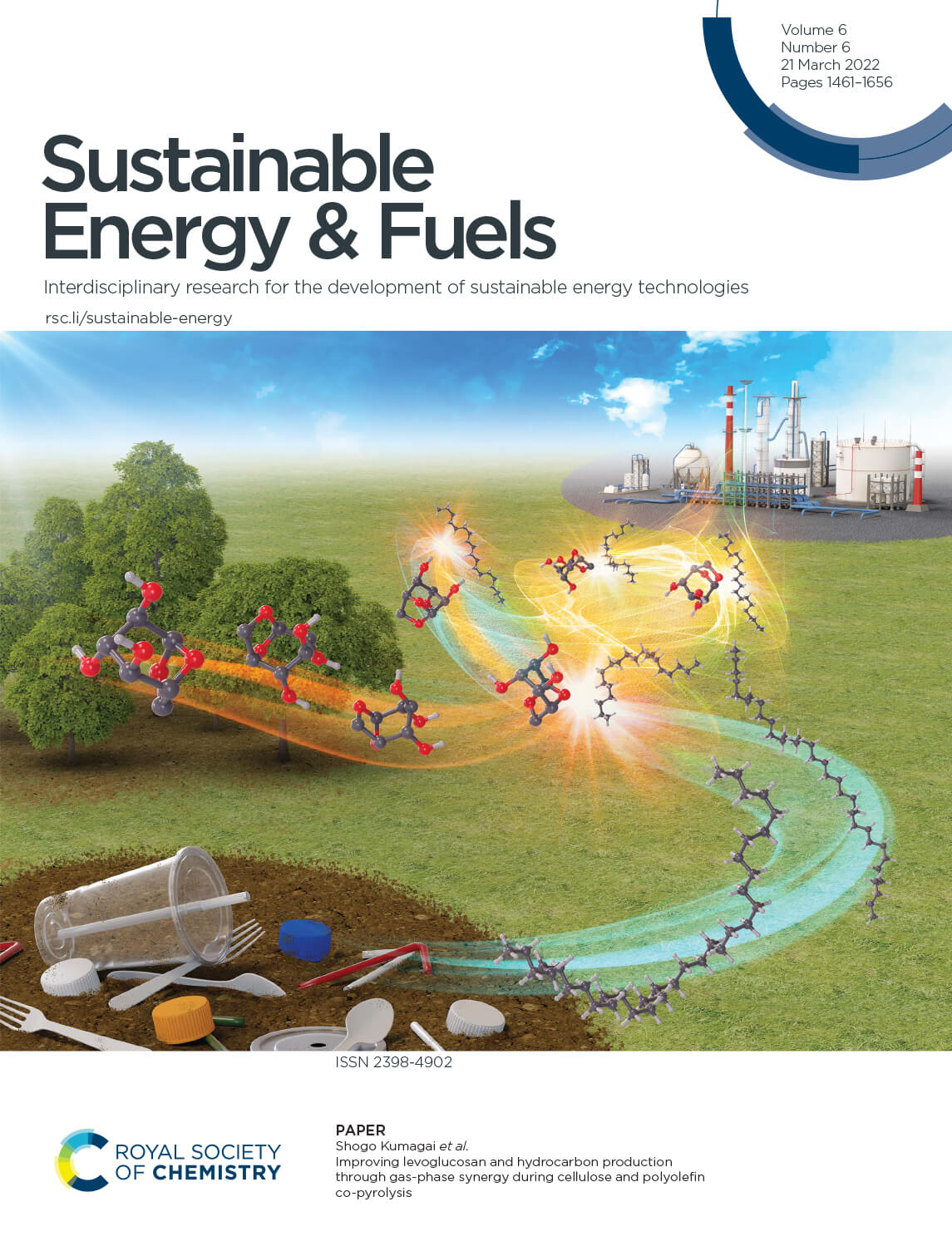

論文雑誌「Sustainable Energy & Fuels」のカバーピクチャーを制作しました[東北大学]

弊社で制作しました東北大学 熊谷将吾先生 ご依頼のカバーアートが

イギリスの王立化学会発行の学術雑誌 Sustainable Energy & Fuels

2022年3月号に選ばれました。

Client

東北大学

大学院環境科学研究科

熊谷将吾先生

大学院環境科学研究科

熊谷将吾先生

Journal

Sustainable Energy & Fuels

March 11, 2022, Volume 4, Issue 3 Link

March 11, 2022, Volume 4, Issue 3 Link

Improving levoglucosan and hydrocarbon production through gas-phase synergy during cellulose and polyolefin co-pyrolysis

Shengyu Xie, Chuan Ma, Shogo Kumagai, Yusuke Takahashi, Tomohito Kameda, Yuko Saito and Toshiaki Yoshioka

The co-pyrolysis of biomass and plastic is a promising technology for producing valuable chemicals. Herein, we report a novel split-flow tube reactor designed to focus on gas-phase synergy during the co-pyrolysis of cellulose and polyolefins, such as polyethylene (PE) and polypropylene (PP), at 650 °C in various blending proportions. The split-flow tube reactor significantly enhances levoglucosan (LG) recovery compared with the conventional straight-tube reactor, resulting in 3.1- and 2.1-times higher yields than those theoretically calculated (2.8 wt%) for 1 : 2 w/w cellulose/PE and 1 : 2 w/w cellulose/PP. In addition, gas-phase interactions between cellulose and polyolefin pyrolyzates were found to improve hydrocarbon-oil production by enhancing the decomposition of polyolefin-derived wax. These findings reveal that gas-phase pyrolytic interactions have significant potential for enhancing the production of chemical feedstocks or fuels from biomass and plastic waste.

Link

Shengyu Xie, Chuan Ma, Shogo Kumagai, Yusuke Takahashi, Tomohito Kameda, Yuko Saito and Toshiaki Yoshioka

The co-pyrolysis of biomass and plastic is a promising technology for producing valuable chemicals. Herein, we report a novel split-flow tube reactor designed to focus on gas-phase synergy during the co-pyrolysis of cellulose and polyolefins, such as polyethylene (PE) and polypropylene (PP), at 650 °C in various blending proportions. The split-flow tube reactor significantly enhances levoglucosan (LG) recovery compared with the conventional straight-tube reactor, resulting in 3.1- and 2.1-times higher yields than those theoretically calculated (2.8 wt%) for 1 : 2 w/w cellulose/PE and 1 : 2 w/w cellulose/PP. In addition, gas-phase interactions between cellulose and polyolefin pyrolyzates were found to improve hydrocarbon-oil production by enhancing the decomposition of polyolefin-derived wax. These findings reveal that gas-phase pyrolytic interactions have significant potential for enhancing the production of chemical feedstocks or fuels from biomass and plastic waste.

Link